Why framework?

Framework houses are a simple and efficient option of building a dwelling house. An element is a wood framework wall unit of the house prefabricated in our factory.

FAST BUILT

COSY

ECOLOGICAL

Framework houses

Element houses are a simple and efficient option of building a dwelling house. An element is a wood framework wall unit of the house prefabricated in our factory. Before starting production of the house a detailed drawing is made for each wall. House walls are made with outside finish in our factory in accordance with the customer’s wishes. The outer walls include weatherboards, wind insulation, thermal insulation, ventilation, door and window spaces with casings, and, if a customer wishes so, inside finishing materials.

Wooden framework houseWooden framework houseWooden framework house

The prefabricated wall unit is transported to your building site and assembled on the foundation within three days on average. An easy assembly and installation of windows and doors makes construction much faster thereby fully preventing negative impact of precipitation on the quality of structures.

About LISKANDAS, LLC

The company has gained vast experience in manufacturing timber houses since 1994. We are proud of annual increase in sales both in Lithuania and abroad. Majority of our produce goes to the Nordic countries (Norway, Sweden, Denmark, and Iceland) as well as to the UK. Up to 95% of all the houses manufactured goes for export. We are happy to be able to use Scandinavian experience in construction of Lithuanian houses.

Frequently asked questions about element houses:

What is an element house? How does it differ from a framework house?

It is a house built of prefabricated elements. An element is a wall unit of the house prefabricated on the basis of wood framework. It consists of include weatherboards, wind insulation, thermal insulation, ventilation and inside finishing materials (wood chipboard + gypsum board or lining board). Both a framework house and an element house are essentially the same. Terminologically, a framework house is built on the site from the very start using precut timber or precast frames, while an element house is built of precast elements, i.e. wall units.

What are advantages and disadvantages of an element house?

Advantages: fast built, ecological, warm, reasonable price. Disadvantages: mismatch with the Lithuanian conventional attitude giving preference to a brick house, light wooden structures have poorer impact absorption performance.

What is the price of a square metre of a framework house and what’s included?

We build houses based on individual designs. Our experience tells that houses of equal square area may significantly vary in price, depending on wall area, flooring and variety of materials used. The price of a conventional framework house starts from 1 500 Litas per one square metre. The price includes outside finish, full heat insulation, partial interior finish, roof, windows, and doors. Foundation, electrical and plumbing installation, interior finish completion, furniture, etc are not included.

What is the lifetime of a framework house?

If a house has been built in compliance with all the rules for construction of a framework house, such house will serve for 100 and more years. Weatherboards might need replacement after 50 years, while the main structures of the house should remain without changes.

How do you maintain a framework house?

Firstly, a house should be built by experts following the technologies developed through centuries. A completed house does not require any special maintenance. Just renew paint of the weatherboards every few years. Modern high-grade paints last for 10 to 15 years.

How long does it take to build a framework house?

Prefabrication of elements for an average size house of 150 sq metres takes 4 weeks. Onsite building takes another 10-12 weeks, thereafter a house with a partial interior finish is ready.

What is thermal resistance of a framework house?

Thermal insulation is also used in structural part of a framework house. Taking into account value for money, thermal resistance ratio of outside walls of our houses is 4-5, and that of the roof 6-7.

Siaudiniai stogai, LLC based in Panevezys, Lithuania. Siaudiniai stogai, LLC products and activities are:

Straw roofs - coating and restoration

Shingle roofs -coating, restoration

Thatch roofs, summerhouses

Log house -design, log home construction.

Panel house- design, prefabricated houses.

Frame houses -desing, frame houses.

Sometimes our clients do not find one of our standard designs suitable for their needs and ask us to build them a custom cabin.

OPTIONS:

– Canopy overhang;

– Veranda with decking;

– Extra wall height;

– Loft space;

– Double glazing or safety glass;

– Alternative roof coverings;

– Gutter system.

P1 Pavilion KAROLINA 2.4x2.4 m

Dimensions 2,4x2,4 m. Roof, walls, floor 18 mm planed planks Lattices:

full range, half-lattices rectangular, half-lattices curved Possible changes: flower box, blind shields for pavilion

P2 Pavilion OVAL KAROLINA 3,0x4,0m, treated

Dimensions 3,0x4,0, one entrance, roof, walls, floor 18 mm planed planks

Lattices: full range, half-lattices rectangular, half-lattices curved Possible

changes: flower box, additional entrance and blind shields for pavilion

P3 Pavilion OVAL MARGARITA 3,0x4,0 m, treated

Dimensions 3,0x4,0 m. 9 windows and 1 door included Roof, walls, floor 18 mm planed planks Possible changes: flower box, additional doors and

blinds shields for pavilion

P4 Pavilion MARGARITA 3,0x3,0 m, treated

Dimensions 3,0x3,0 m 4 windows and 1 door included Roof, walls, floor 18 mm planed planks Possible changes: flower box, additional windows for pavilion

P5 Pavilion KAROLINA 3,0x3,0 m

Dimensions 3,0x3,0 m Roof, walls, floor 18 mm planed planks

Lattices: full range, half-lattices rectangular, half-lattices curved

Possible changes: flower box, blind shields for pavilion

P6 Pavilion AUSRA 3,0x3,0 m, treated

Dimensions 3,0x3,0 m Roof, walls, floor 18 mm planed planks

Lattices: full range, half-lattices rectangular, half-lattices curved

Possible changes: flower box, blind shields for pavilion

P7 Garden set VESA (for pavilion 2.4 m)

Spruce 60 mm thickness. Dimensions, LxWxH, m: Octagonal table: 1,08x1,08x0,76;7pcs. benches: 0,94x0,37x0,44,

P8 Garden set VESA-3 (for pavilion 3,0 m)

Spruce 60mm thickness. Dimensions, LxWxH, m: Octagonal table: 1,43x1,43x0,76, 7pcs. benches: 1,14x0,37x0,44

Other Siaudiniai stogai, LLC activities are:

Sell thatching roof

Thatching roof, wooden gazebo with thatch roof, long straw roof. We work in all Europe.

Sell water reed thatch

Company cut and sell water reed, long straw, also we making thatch roofs and wooden gazebo. We cutting water reed just by the sea, because when water reed is stronger and yellow-white color

Thank you for taking the time to go through our business profile. If there are any question, inquiry or comments, please feel free to contact us.

- Straw roofs

- shingle roofscoating and restoration

- thatch roofs

- thatch roofs in Lithuania

- thatched roofs

- summerhouses log houses

- frame hauses

- panel houses straw roofs in lithuania

- shingle roofs in Lithuania

- thatched roofs in Lithuania

- summerhouses in lithuania houses in lithuania

- straw

- roof

- reed

- frame house construction company in Lithuania

- construction company in Lithuania

- log house construction company in Lithuania

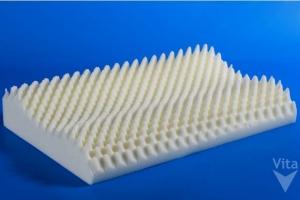

The pillows produced by the foam manufacturing plant Vita Blatic International, LLC have been tested by the respected laboratory Thomson Research Associates (Europe). We have been issued a certificate verifying that the polyurethane foam pillows fully meet the Ultra-Fresh antimicrobial requirements. This is another international recognition of high professionalism of the manufacturers of Lithuanian foam and the quality of our products.

We pay attention not only to the quality of our products, but to the proper storage of chemical raw materials, transportation and safe production technology. The specialists of the experienced manufacturer of chemical raw materials BorsodChem have carried out an inspection of safety of chemical raw materials at our plant and evaluated it as "A" Excellent.

Vita Blatic International, LLC was incorporated in 1997. Foam manufacturing plant was built in Southern Lithuania, on the outskirts of Alytus . The company belongs (is part of) the "VITA GROUP ", one of the largest polyurethane producers in the world. Overall investment including construction of the state-of-the-art manufacturing facility and purchase of foam production and processing lines, incorporating the latest technology, totalled to EUR 18.3 million. The company is committed to continuous expansion of its manufacturing and technology base. Highest quality raw materials are exclusively supplied by the most prominent companies of the chemical industry. The company is the leader of PU foam market in the Baltic states. The production is exported into 12 countries. The production conforms to the highest EU requirements for quality and environment protection.

Company management principles:

ensurance of requirements for occupational safety and health;

"Vita Group" company performance model;

quality management activities.

Smart House – it’s a system which unites all house equipment: security, air conditioner, heater, ventilation, illumination, blinds control, etc. Smart House System controlls all house equipment.System is controlled directly at house (by control block on the walls and remote control panel) internet, mobile and wired telephones. The benefit that Smart House System gives:

• improvess your life quality;

• helps you to protect your house;

• saves your money.

While implanting Smart House System, traditional installation switches are changed by digital equipment which executes information exchange by a magistral hook that unites all house equipment. Magistral 4 thread hook is installed beside 230V hooks.

Improves your life quality

Smart House System is adapted to your needs and gives many new possibilities and increases your house comfort.

• You can regulate illumination by scenario projected in advance, by day time, by day light intensity, by people being place.

• You can control blinds and gate automatically and manually, by time, exterior climate or together with illumination scenes.

• Conditioning and heating equipment will be automatically regulated by time, set scenes, people being place. The house will be ventilated when people are absent and heating is switched on before you come back home.

• It is easy to adapt this system to your needs and there is no need to hammer the walls and do any repair work.

• You will be able to observe and set all command and control functions in one computer. Use of control programme is simple and easy to learn. You will see graphic premises view and its controllable parameters.

It helps to protect your house

Smart House System is very reliable and helps to protect your house.

• In case of fire it will turn on all lamps, sirens and air conditioner and ventilation systems will be set in such a way that fire could not spread.

• If you leave the house without turning off household devices, the Smart House System will turn them off.

• When you are not at home, you will be able to set illumination regime which will imitate your being at house and will turn on and turn off the illumination.

• If someone breaks into your house or an accident happens, the Smart House System will send you and indicated persons messages and security or other services.

It saves your money

Once the Smart House System is installed, the house maintenance expenses will reduce.

• While installing the Smart House System, 60% less of hooks is used.

• The System saves up to 50% of usedelectric energy.

• Illumination equipment and light sources last twice longer.

• When the Smart House System controls the heating system, heating expenses reduce up to 30%.

• In summer time blinds automatic control reduces premises’sun heating and reduces electric energy quantity used by conditioning equipment.

- Blinds

- introduces

- Clever House

- system

- practices retail and wholesale trade of electro technic materials

- illumination equipment and blinds

- design

- style

- colors

- interior

- open air and industriallamps

- illumination equipment

- architectural illumination compositions

- illumination for special use

- automatic control systems EIB

- KNX

- My Home of Clever House

- ardena

- uab ardena

- smart house

●Agriculture & Livestock ●Automotive ●Building, Construction & Public Works ●Business Services ●Chemicals & Pharmaceuticals ●Computers & Software ●Education & Research ●Electrical & Electronic Equipment ●Employment ●Energy & Raw Materials ●Entertainment ●Finance, Legal & Insurance ●Food & Related Products ●Glass & Construction Materials ●Government & Law ●Health & Beauty ●Home & Garden ●Leather ●Luxury & Leisure Products ●Metallurgy & Minerals ●eShops ●Paper & Cardboard ●Precision Equipment ●Printing & Publishing ●Real Estate ●Retail & Shopping ●Rubber & Plastics ●Science & Environment ●Shoes & Footwear ●Small Business ●Society & Culture ●Sports ●Telecommunications ●Textiles & Clothing ●Transport & Related Services ●Travel & Tourism ●Wood & Wood Processing

During the past years perception of lighting application in buildings of sacramental purpose has expanded since it is not exclusively natural lighting that is being used, but artificial next to it also. Lighting design that was first introduced in the market several decades ago is still considered a novelty in Lithuania. In 2004 professional designer Antanas Pocevičius has designed lighting for renovated Church of Jesus Christ Resurrection.

About GAUDRE, LLC

GAUDRE, LLC is one of the leading companies in lighting market in Lithuania. Our goals are company’s competence, skills, reliability and high quality of supplied products and provided services. This includes all fields of our operations: lighting, EIB and DALI lighting control systems, electricity installations and electrical heating systems. We are offering modern integrated solutions and their related services. Efficiency of our services is ensured due to high skills of our technicians, professionalism and attention given to the client. Our range of products is a perfect choice for implementing technical requirements of various projects, characteristic by optimum price, high quality and economic value.

We are the ones to provide You with high qualified solutions.

Qualified solutions, they are more than just a design and technical specs of a product. It’s a creative process requiring deep knowledge of lighting theory, human psychology and electronics, as well as experience in implementation of practical solutions. Our knowledge is a promise of successful implementation of visions by architects and our clients, as well as revealing possibilities of light use. We are promising long-term and cost effective solutions depending not only from technologies or modern art, it’s also experience in production and design.

Construction of houses pre-fabricated in plants has been the most popular house-building technology in the world for several decades. For example, in US 90% of houses have been built on the basis of wooden frameworks. In Sweden 80% of all houses have been made of wood and in Scotland - 48%. These numbers are constantly increasing in other countries too. This building method is considered to be economical, environment-friendly and requires low maintenance costs. Modern architectural tendencies, new building materials and the latest technologies provide more and more possibilities for production of panel houses.

European countries started developing production of panel houses 50 years ago. In Germany, Norway, Sweden and some other countries the majority of residents live in panel houses. Therefore panel houses are sometimes referred to as houses of the 21st century.

During recent decades the production technology of such houses has improved considerably due to the fact that modern equipment and building materials have been introduced. Modern panel houses not only stand their ground if compared to brick houses and timber houses, but have even surpassed them.

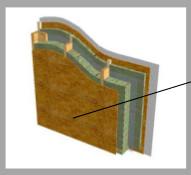

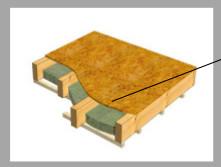

A panel house is constructed of panels which are made as follows: OSB boards are nailed to a wooden frame on the outside and on the inside. The inside of such a panel is then filled with stone wool and this allows to achieve the required thermal resistance. Such construction of buildings guarantees stable characteristics of thermal resistance during any season of the year. Houses built in accordance with such technologies are environmentally-friendly, they have good heat and energy saving characteristics and they are suited for living in them permanently.

Why a panel house is a good choice?

QUALITY

Automated production - ensuring high precision of products

Standard units - guarantee the absence of frost bridges

Production is fully controlled

Specially trained personnel works in the production process

SPEED

House assembly takes 3 to 5 days.

Contact us only once and specialists of UAB Kriaute will produce and assemble a house under a typical or individual project. Ready-made panels of up to 12 m length help to save time on the construction site.

House- assembly work can be done all year round

GUARANTEES

Only certified materials are used for production of houses

Post-guarantee service is provided

PRICE

Short assembly time - workforce to be hired for a shorter time

Light- weight building elements - simpler foundations

Pre-fabricated elements of a house are delivered to the construction site in due time - you do not have to take measures of precaution against theft.

INDIVIDUAL DESIGNING

KRIAUTE, LLC company's designers use a special computer program for preparing the structural drawings of a house. With the help of our designer a client himself can design a dream house, or he can choose an already available typical project. You are welcome to have a cup of coffee or tea and to see a sample house built by our company.

HOUSE CONSTRUCTION

Separating walls and separating floors

One of the most important requirements for separating walls and separating floors is their acoustic properties (i.e. airborne sound insulation). The typical assemblies of separating walls and separating floors used by our company allow us to comply with the sound insulation standards. Inside separating bearing walls achieve the value of at least 52 db, whereas inside separating non-bearing walls achieve the value of at least 36 db.

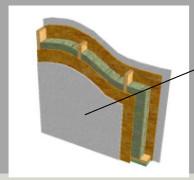

Outside walls and roof panels

One of the most important requirements for outside walls and roof panels is thermal insulation. Proper assembly of panels allows us to achieve in these structures the maximum thermal resistance which complies with the current requirements. The outside walls achieve the thermal resistance value of 5 sq. m K/W and the roof - the value of 6 sq. m K/W.

STANDARD STRUCTURE OF TIMBER-FRAME PANEL HOUSES

EXTERNAL WALLS

EXTERNAL WALLS

Wooden outside boards, clinker bricks, thermoinsulating panel

OSB board 12 mm

Wooden frames 45 x 145 mm

Thermal insulation 150 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

OSB board 12 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 W/m2K

CEILING

CEILING

OSB board with tongue 22 mm

Wooden frames 60 / 45 x 220/ 200 mm

Sound insulation 100 mm

Wooden square beams 45 x 45 mm

Plaster board 12.5 mm

INTERIOR LOAD-BEARING WALLS / PARTITIONS

INTERIOR LOAD-BEARING WALLS / PARTITIONS

Plaster board 12.5 mm

OSB board 12 mm

Wooden frames 45 x 145/ 95/ 75/45 mm

Sound insulation 150/100/70/50 mm

OSB board 12 mm

Plaster board 12.5 mm

ROOFPANELS

ROOFPANELS

Wooden square beams 45 x 45 mm

Wooden square beams 25 x 45 mm

Diffuse film

Rafter 60/ 45 x 195 /220 mm

Thermal insulation 2 x 100 / 3 x 75 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 / 0.18 W/m2K

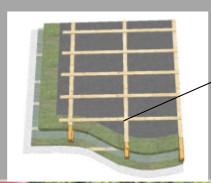

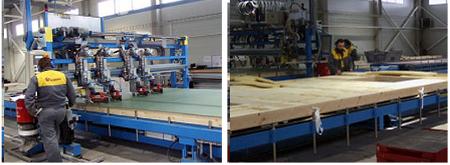

PRODUCTION PROCESS

Our panel house production plant was launched in the second quarter of 2007. The manufacturing floor space is 10 000 m2, this includes space used for both - manufacturing and storage purposes.

Panel houses are produced by highly qualified specialists.

The estimated production yield is 300 average size residential houses per year.

The basic elements of a panel house such as outside and inside walls, ceiling and roof (except roof covering, which is to be chosen by a client) are made indoors in accordance with drawings. Every house element passes quality control in the production-shop. This is how high quality of products is achieved in our company. The bearing structure of a panel house consists of wooden elements. Highest-quality wood with 15 % moisture content is used for production of panel house elements. Dried wood does not shrink or turn. This is an environmentally friendly material which makes your home cosy and comfortable.

KRIAUTE, LLC cooperates with architects and designers. Our engineers can adjust the equipment to comply with the requirements of the project. Production takes place indoors; therefore, the impact of atmosphere is avoided.

In the course of production process we focus our attention on technical solutions ensuring high quality of products.

Specially-trained highly-skilled employees work in the production area.

Pre-fabricated elements are made by using computerized equipment, therefore the human impact on precision and quality of the final product is reduced.

To private individuals and entities the KRIAUTE, LLC offers building warm, economic and safe houses. Modern Swedish-make equipment, qualified staff and use of certified materials warrant high product quality and prompt delivery.

- Construction of houses

- prefabricated in plants

- popular house building

- technology

- wooden frameworks Individual panel houses

- Individual designing Panel houses

- House construction

- Production process

- Garden houses

- Summerhouses Bathhouses

- Wooden windows

- doors

- furniture

- wood construction

- Residential houses

- industrial

- commercial

- administrative buildings and business centers

- manufacturer

- wood

- panel house

- kriaute

- uab kriaute