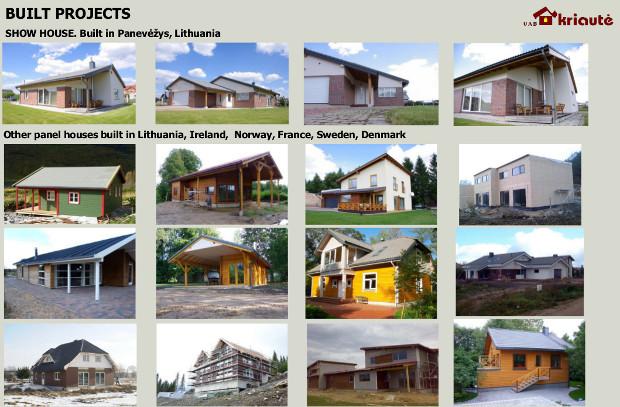

KRIAUTE, LLC was founded in 1987, in Lithuania. In 2007, the company finished the implementation of the project Manufacture of modern TIMBER FRAME PANEL HOUSES on the basis of innovative technologies which was realized under the Single Programming Document. In the second quarter of 2007 we opened a Timber frame panel house production plant, which is one of the most modern plants of this kind in the Baltic States. We offer warm, economical and safe houses to private clients and companies.

Modern production facilities obtained from Sweden, highly-qualified personnel and the use of certified building materials guarantee rapid production process and high quality of the products. In 2007, KRIAUTE, LLC was awarded with the medal of the Ministry of Economy "Merits for Business" in the nomination "Development of Small and Mid-Size Business in Counties" (Panevezys County).

Assessment Commission's Protocol No. IA-119, valid from 25 April 2008 to 2013 April 25, grants the right to KRIAUTE, LLC to design separate parts of buildings, to construct a building or a separate part of a building and to maintain objects of Cultural heritage.

The company's modern manufacturing facilities are based on a 5-hectare site in the industrial part of Panevezys. We have 10 000 m2 of manufacturing space, where we produce structural and planed wood, different kinds of joinery products, wooden parts for furniture, metal products and metal constructions, garden houses and outdoor furniture.

Transportation services as well as timber drying, tenoning and planing services are also provided.

Our company cherishes its reputation. We carefully meet our commitments and seek to remain a reliable partner.

QUALITY

Our panel house production plant was launched in the second quarter of 2007. The manufacturing floor space is 10 000 m2, this includes space used for both - manufacturing and storage purposes.

Panels are produced by highly qualified specialists using Swedish technology and equipment.

The estimated production yield is 300 average size residential houses per year.

The basic elements of a panel house such as outside and inside walls, ceiling and roof (except roof covering, which is to be chosen by a client) are made indoors (therefore, the impact of atmosphere is avoided).Our engineers adjust the equipment to comply with the requirements of every project. Every house element passes quality control in the production-shop and only specially-trained highly-skilled employees work in the production area. In the course of production process we focus our attention on technical solutions ensuring high quality of products.Pre-fabricated elements are made by using computerized equipment, therefore the human impact on precision and quality of the final product is reduced. This is how high quality of products is achieved in our company.

The load-bearing structure of a panel house consists of wooden elements. Highest-quality wood with 15 % moisture content is used for production of panel house elements. Dried wood does not shrink or turn. We prepare timber in our factory, so we can assure the quality and control timely supply. This is an environmentally friendly material which makes your home cozy and comfortable.

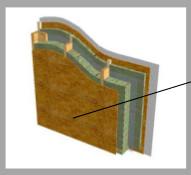

STANDARD STRUCTURE OF TIMBER-FRAME PANEL HOUSES

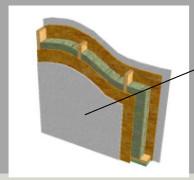

EXTERNAL WALLS

EXTERNAL WALLS

Wooden outside boards, clinker bricks, thermoinsulating panel

OSB board 12 mm

Wooden frames 45 x 145 mm

Thermal insulation 150 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

OSB board 12 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 W/m2K

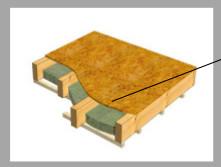

CEILING

CEILING

OSB board with tongue 22 mm

Wooden frames 60 / 45 x 220/ 200 mm

Sound insulation 100 mm

Wooden square beams 45 x 45 mm

Plaster board 12.5 mm

INTERIOR LOAD-BEARING WALLS / PARTITIONS

INTERIOR LOAD-BEARING WALLS / PARTITIONS

Plaster board 12.5 mm

OSB board 12 mm

Wooden frames 45 x 145/ 95/ 75/45 mm

Sound insulation 150/100/70/50 mm

OSB board 12 mm

Plaster board 12.5 mm

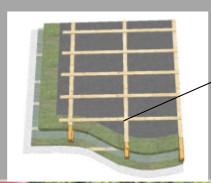

ROOFPANELS

ROOFPANELS

Wooden square beams 45 x 45 mm

Wooden square beams 25 x 45 mm

Diffuse film

Rafter 60/ 45 x 195 /220 mm

Thermal insulation 2 x 100 / 3 x 75 mm

Steam insulation

Wooden square beams 45 x 45 mm

Thermal insulation 50 mm

Plaster board 12.5 mm

Heat transfer coefficient 0.2 / 0.18 W/m2K

MODULAR PAVILIONS / CONTAINERS

Our modular containers are a flexible solution at low prices and can be produced on individual projects for housing, offices, building houses for temporary living, trade buildings and others. On the basis of the modular structure standing containers can be combined in different arrangements vertically and horizontally. We use metal structure where it is needed for stability, the rest of the structure is timber frame. They comply with the requirements for energy effectiveness and eco-design. Different sizes and numerous options for configuring components allows our products to match the requirements of the client.

We can offer fully assembled modules to be delivered on site, or separate panels delivered and assembled on site.

Advantage of our modules is fast assembly and dismantling.

Below you can see a scheme of the system we suggest for our clients. It makes it possible to have all space needed for temporary offices and accommodation. Unlimited number of modules can be placed side by side in a required sequence. They also can be put one on top of the other in max. 3 levels.

WOODEN WINDOWS

Why a wooden window is a good choice?

Wood is a natural long-lasting material which is perfectly suitable for buildings of different architectural styles;

Wooden windows save energy and your money;

Wood has the lowest thermal expansion coefficient if compared to any other materials used for production of windows;

Wooden windows do not accumulate electrostatic charges or dirt.

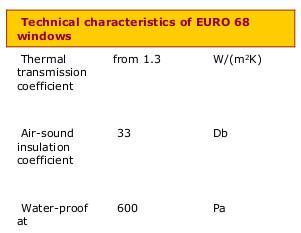

EURO 68/78 profiles of the new generation have a lot of properties which are inconspicuous at first sight, but which are very important and highly-valued by professionals.

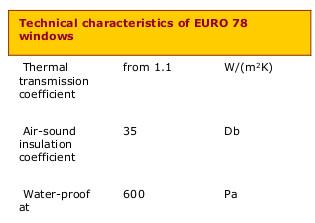

EURO 78

Warm wooden window

EURO 78 windows are 10 mms. thicker than Euro 68, therefore triple glass packets are usually set into them; this improves heat insulation and soundproof characteristics. Components of the window "Euro 78": 78 mm wooden profile made of wood chosen by a client (pine, larch, oak, etc.); German "Siegenia AUBI" fittings with an additional position of micro-ventilation; "Sikkens" paint, which ensures durability and aesthetical looks, is used for painting the windows.

Advantages of EURO 68/78 windows

EURO 68/78 profiles of the new generation with corners rounded more than it was usual and with inclination, which makes painting of the window easier and improves the quality of painting, and which also prevents accumulation of water and dirt and improves the looks of the product.

Tongue connections at the corners of window sash have ventilation of the opening for glass packet installation. The condensed water is removed through the drainage holes in the aluminium mould of the window frame.

The main seal at the bottom of the sash presses not to the aluminium mould, but to the wooden part of the window frame, therefore it does not freeze to it.

The outer horizontal plane of the sash is inclined by 200, thus enabling to easier remove snow, rain or dust.

EURO 68

The most popular wooden windows in Lithuania

Components of the window "Euro 68": 68 mm wooden profile made of wood chosen by a client (pine, larch, oak, etc.);

German "Siegenia AUBI" fittings with an additional position of micro-ventilation; "Sikkens" paint, which ensures durability and aesthetical looks, is used for painting the windows.

We are looking for companies and enterprises that are able to represent our products: panel houses, wooden windows and processed wood in the countries of the European Union and in Scandinavian countries.

We are looking forward for offers leading to a close and mutually beneficial cooperation.

- Individual panel houses

- Individual designing Panel houses

- House construction

- Production process

- Garden houses

- Summerhouses Bathhouses

- Wooden windows

- doors

- furniture

- wood construction

- Residential houses

- industrial

- commercial

- administrative buildings and business centers

- manufacturer

- wood

- baths

- outdoor furniture

- wooden parts for furniture

- wooden Eurotype windows

- panel hauses

- joinery products

- eco windows

- timberframe element houses

- panel houses

- producer of timberframe panel houses, modular pavilions, windows

- kriaute uab

- uab kriaute

Aisvita, LLC Curtain Salon in Vilnius proposes to create a unified interior and the comfort of your home ... Since October 1996, Aisvita, LLC is engaged in this business. Specializes in decorating restaurants, cafes, hotels and private spaces.

We work directly with fabric manufacturers from Germany, England, Austria, France, Italy, Turkey and India. We sell Italian and Polish cornices and their accessories, as well we sell mechanisms for roman blinds, austrian blinds, for screen curtains. Also we can offer a wide range of mechanism for complicated windows.

In our shops you can find wide range of ready made pillows, tablecloths from India, ready made bedcovers and curtains. If you will not be able to find what you need in our shops, just tell us what you like and we will deliver it from our suppliers in a short period of time.

You want household harmony, or maybe you like to shock, or the alignment is not what it seems - our designers will help to solve it all. From the project data to the final order of implementation. High-quality materials and ideas that do not restrict you to a whole surprise. Designed curtains for you - will fulfill your home with more comfort and cosiness.

In shops we sell over 300 types of curtains and also offer a wide range of intermediate curtains.

Rely on professionals!

Screen Curtains

Screen curtains came from Japan, they are particularly suitable for minimalistic style of interior. These are the fabric pieces, horizontally movable aluminum mechanism. Sewn from a variety of materials, slides beautifuly, with the other fabric fragments, the cross wires. This is a great tool to cover the large panoramic windows, you have a convenient window into the center of the field or on the terrace. Currently, it is the most popular means of decorating the windows, which became popular between even the greatest skeptics.

Austrian blinds

This is especially luxurious and splendid curtain type, it is somewhat similar to the roman, but austrian blinds top up with the big-wave gloom. They can also be mixed with day curtains as well as night, or perhaps both mixed with some applications taken from the silk material, such as flowers. These curtains will fit with natural silk, organza fabrics, non-traditionaly standing taft.

Roman blinds

This is often referred to as Roman blinds. Its special mechanism helps to blend or gather on top of the window area, or just blends in window niche. These curtains can be sewn from thin fabrics as organza, transparent fabrics, thick and even very thick fabrics like tapestry. Sewn to the lining, and without it. Roman blinds may be carried out as the shade option, only then they should be coordinated with the day curtains. The method of attachment allows the adaptation of the roman blind to a variety of windows.

Classical curtains

Everyone dreams of a comfortable and stylish home in which aesthetics and harmony prevails. Curtains are essential for us and it only makes our home warm and comfortable.

Day time curtains sewn from lightweight, bright, matt and transparent fabrics. They can be short or long, up to the floor, or even lying on it. If the lights or a close neighbor is not the problem than day curtains will be enough, if not there might be a need for a darker night material, there are plenty of different colours and designs, but if this is not enough than blackout material will solve it all, it is possible to sew it with any dark night material.

There are also intermediate curtains which mounted one. They are usually sewn from denser but less-transparent fabrics, they must be relatively light and bright, that the window could be slightly covered. Where and how to hang?

Day and night curtains are hanged on the cornices. They are wooden, metal, affixed to the wall, as well as plastic, metal is affixed to the ceiling. It is important that the molding decoration piece must be matched not only to the curtains but also tothe room interior.

Curtains can be decorated with stamped metal rings. Curtains will fall with beautiful large waves.

Screens, autrian blinds, roman blinds can be mounted to the ceiling, window niche with special holders. Cornices are imported from Spain, Italy, Poland and Germany. Screens, romand blind, austrian blind mechanisms imported from Italy. For customer's request we install and hang all the other systems for curtains. We guarantee the quality of work!

Tablecloths, bedcovers, pillows, ready-made curtains

We sell various finished tablecloths, pillows, curtains, bedcovers. These products are of various sizes, color and patterns. If you can not find suitable pillows, tablecloths, bedspreads or ready made curtains , we can sew one from the material and appropriate model chosen.

- Curtain salon

- designed curtains

- curtains

- roman blinds

- screen blinds

- austrian blinds

- cornices

- mechanisms for roman blinds

- for screen curtains

- ready made pillows

- tablecloths

- ready made bedcovers and curtains

- Sewing of all types of curtains

- screens

- hitting all types of cornises including mechanisms for roman curtains

- textile fabrics

Are you looking for original ideas and yet untried materials? You can discover excellent quality of articles, design of forms and new possibilities of creation by trying the technology of artificial marble. The technology of artificial marble was designed in the USA. It has repeatedly received international awards for the possibilities to create articles of excellent qualities, design of forms and new production. Production of cultured marble represented the United States of America among 28 countries in the international fair of Geneva for two times and both times it was awarded with silver medal.

In Lithuania the production of this unique product was started in 1998 on behalf of "BALTIJOS MARMURAS".

Currently UAB "Baltijos marmuras" manufactures three types of production:

• cultured marble;

• cultured granite;

• solid surface “Dura Stone” (similar to “Corian” or “Cristalan”).

One of the basic advantages of the company "BALTIJOS MARMURAS" is the flexibility of production solutions. Various forms and colour gamma of products provide unlimited opportunities for the harmonization of interior colours and styles. This technology allows to obtain various colours that suit modern interior.

The production made from cultured marble or cultured granite especially fits in with the bathroom interior, i. e., sinks with tabletops of various forms and sizes, tables, windowsills, etc. Solid surface “Dura Stone” is one of the most durable and modern combinations of natural and synthetic materials. Solid surface is used for the production of tabletops, sinks, bars, wall slabs, windowsills and other products of various configurations and dimensions.

The areas of application of production manufactured by the company "UAB BALTIJOS MARMURAS" can be limited not by the properties of the material itself, but rather by the person's imagination. The imagination, of course, has no limits, therefore the possibilities of usage of these durable, nice, easy care materials certainly have not yet been explored as the articles produced by the company "BALTIJOS MARMURAS" are also easily fitted with other materials, e. g., metal, ceramics, wood, etc. Conforming to the highest quality requirements the production of "UAB

BALTIJOS MARMURAS" is certified in Lithuania

Solid surface "Dura Stone"

Solid surface "Dura Stone"

Produced according to the American technology solid surface "Dura Stone" is similar to "Corian", "Cristalan" and "Wilsonart" materials based on its properties. By using this homogenous material architects, designers and each one of us can implement our various dreams and enjoy a freedom of imagination. Solid surface "Dura Stone" is characterized with a wide range of applications. The material is used for the interiors of restaurants, cafes, bars, hotels, banks and offices; the production of kitchen, bathroom and laboratory tabletops; wall slaps, decoration elements. In addition, solid surface "Dura Stone" is used for the production of sinks integrated (casted) into tabletop.

Solid surface is resistant to scratches, various chemical liquids and is easy to clean. It is one of the most durable and modern combinations of natural and synthetic materials.

Being non-porous the structure of material does not absorb liquids and thus prevent from stains and spread of bacteria. In addition, the surface of these articles is warm and able to reach ambient temperature. Articles are characterized with easy care and restoration; scratches are simply removed by scrubbing.

Properties of solid surface “Dura Stone” are as follows:

- firm and durable,

- hygienic,

- seamless;

- resistant to moisture absorption;

- scratches are removed by simple scrubbing,

- resistant to heat up to +220°C,

- resistant to various chemicals,

- easy to mount,

- easy to restore and repair,

- many ways of formation;

- easy application with various materials,

- resistant to UV rays,

- wide range of colours.

Cultured marble

Cultured marble

Articles of cultured marble are produced from granulated marble powder and special binders. Cultured marble articles are of white colour and their surface is, at first glance, very similar to that of the ceramics.

However, the main advantage of cultured marble is the possibility to implement all ideas as the articles are produced for individual orders. Tabletops with sinks are connected in a seamless way as they are produced by casting. The form, place and number of sinks on tabletop can vary upon client's wish. The surface of cultured marble is smooth and glossy. Tabletops with sinks made of cultured marble and cultured granite may be fitted to various types of bathroom furniture. Cultured marble is also used for the production of white polished windowsills.

Cultured granite "SGA"

Cultured granite "SGA"

Articles of cultured granite are produced from shredded artificial granite granules and special binders. Articles of cultured granite may have both glossy and matted surface. Cultured granite can be used for casting of various articles: basins with tabletops of various forms and sizes with cast-in-place sinks of the same colour, windowsills, tables of various forms and other original production. Tabletops with sinks are connected in a seamless way as they are produced by casting. The form, place and number of sinks on tabletop can vary upon client's wish. Articles are absolutely resistant to moisture.

Become our partner

We invite furniture production companies, designers, architects and construction companies for cooperation.

We provide our partners with comprehensive information, production samples and catalogues.

We offer favourable prices and contract conditions.

- Marble and natural stones

- granite

- bathrooms

- furniture and fittings

- kitchens

- furnishing

- furniture for kitchens

- furniture

- hotels

- bars

- cafés and restaurants

- kitchen table tops

- kitchen sinks

- bathroom wash basins

- basins

- baltijos marmuras, llc

- technology of artificial marble

- cultured marble

- baltijos marmuras, uab

- uab baltijos marmuras

CE Marking: • CE mark is a declaration of the responsible person, that product complies with the requirements of EU which extend on the given product, and corresponding compliance evaluation procedures have been executed. Abbreviation "CE" in French designates "Conformité Européene", that means European acknowledgement.

• CE Marking provides free movement of marked product in European Fair Trade Association and European Union single market.

• CE Marking is obligatory and each product should be marked before it gets into the market, unless there are other references in EU directives. Product cannot be marked with a CE Mark if there is no reference about that in EU directives.

• CE Marking is obligatory to:

all new products, whether they are made in European Union or in third countries;

imported and used products from third countries;

modified products, to which directives are applied as to a new products.

• Manufacturer or its authorized representative in the European Union has to mark a product. CE Mark should be the certain form. At resizing CE Mark should retain proportion. The smallest height of a mark can be 5 mm.

• CE Mark should be put on a product or on its table of data so that the mark would be visible, legible and nonerasable. If it is impossible to make it or it is unessential from features of a product, the mark should be put on packing if it exists, and on accompanying documents if such documents are specified in related directives.

onformity evaluation procedure

Each product in EU market should be marked with a CE mark, unless there are other references in EU directives. First of all, the procedure of conformity evaluation is fulfilled. Then the manufacturer or its authorized representative prepares CE declaration of conformity and later on he can mark the product with a CE mark. Manufacturers from foreign countries has to follow requirements of EU which extend on the given product ant to carry out all the conformity evaluation procedures.

Conformity evaluation procedure in EGSC:

1. Application. The client, who wants to certificate products, should deliver the application to EGSC. To the product maintenance manual in Lithuanian language and normative documents regulating the requirements for the product, other documents are to be attached.

2. EGSC investigates the application

3. The contract on carrying out conformity evaluation works between the client and EGSC is signed.

4. Conformity with the requirements of the product is being checked by performing testing in EGSC Testing center or in other testing laboratories.

5. Test report is made out.

6. Conformance of a product to the requirements of normative documents is evaluated on the basis of Test report or other documents. An account on conformity is prepared.

7. At the positive decision about product conformity the CE Certificate of Conformity is made out.

8. At the negative result the Test report and the copy of the decision about non-conformance at the request is made out.

NOTE. Products can be certificated on the basis of the documents which have been given out by others accredited certification bodies and testing laboratories, if:

a) those documents are given out by certification bodies and testing laboratories, who are accredited by European Organization on Accreditation (EA) agreements on a multilateral recognition signatories.

b) those documents are given out by certification bodies and testing laboratories, who are in partnership with EGSC or EGSC notifies their competence.

About ELEKTROTECHNINIU GAMINIU SERTIFIKAVIMO CENTRAS, LLC

Public enterprise “ELEKTROTECHNINIŲ GAMINIŲ SERTIFIKAVIMO CENTRAS” was founded on 1992 December 15th, by the order of Ministry of Economy and Trade of the Republic of Lithuania N r. 355. In 1996 the enterprise was reorganized in to a Private Limited Company “CERTIFICATION CENTER OF ELECTROTECHNICAL PRODUCTS” (UAB “ELEKTROTECHNINIŲ GAMINIŲ SERTIFIKAVIMO CENTRAS” (EGSC)).

In November 1995 EGSC has been accredited by the Lithuanian National Accreditation Bureau to carry out certification of electrotechnical products, and EGSC Testing center – to carry out of testing of electrotechnical products. Year by year the EGSC has accumulated experience and knowledge, tried to achieve a recognition in Lithuania, in foreign countries and has expanded a scope of activity too.

Today Certificates of Conformity and testing results given out by EGSC are admitted not only in Lithuania, but in the European Union too. EGSC participates in work of CCA, CENELEC, cooperates with Lithuanian and foreign conformity assessment bodies also testing laboratories.

From 2004 EGSC is also a Notified Body under Low Voltage Directive (73/23/EEC and Amendment 96/68/EEC) on the harmonization of the laws of Member States relating to electrical equipment designed (from 2007-01-16 validity 2006/95/EC) for use within certain voltage limits (CE marking).

- certification of electrotechnical products

- testing of electrotechnical products

- evaluation of the compliance with the requirements of the Low Voltage Directive

- consultations on CE marking

- service of weights

- metrology: checking and calibration

- maintenance

- installation

- modernization of mechanical weights into electronic

- rent of standard meters

- National Accreditation

- Certificates of Conformity and testing

- assessment bodies

- testing laboratories

Bricks have been the most popular building material since ancient times until the present days. A brick wall has many advantages such as good thermal and sound insulation, it also holds the load. Brick facades as well are exceptionally beautiful. However, thick brick walls are now the matter of the past. Today the construction of a modern wall is made out of several layers and bricks are laid only on the outside. The layer width of such wall is 85-120 mm. Such facade can be put on a foundation as well as hung on the retaining walls and structures. Steel brackets for brick veneer facades not only give us this possibility but also allow us to fulfill the bravest architectural solutions.

Very often big shop windows are built on the first floor of the building while brick decoration starts only on the second or even the third floor. Such projects are very popular in big cities. The main principle of such assembling is as follows: stainless steel brackets are adapted to holding reinforced concrete structure one brick at a distance. Bricklaying can be varied: one brick row or if you need several rows of bricks can be hung below the bracket. At first the armature is placed into mortar above the first row of bricks and then the second row of bricks is placed on the bracket. Later the other two brick rows are also reinforced with armature.

UAB “BAUTOPAS” has been developing and manufacturing various BAUT® brand components for brick veneer facades for already 15 years. In particular there are various forms of stainless steel brackets. Most of all the company is proud of hooks of galvanized and stainless steel wire. It is possible to make any architectural solution lintel up to 2 meters by using the hooks together with armature. For the lintels that are wider than 2 meters, steel brackets will be needed additionally. The amount of steel brackets is calculated according to the current load. A wide variety of joints allows to perform a wide range of architectural solutions. Furthermore, price of BAUT® products is lower, which stands out UAB “BAUTOPAS” from the similar systems in the world market.

Those, who are interested in steel brackets for brick veneer facades, can form an opinion that BAUT® system is designed only for multistory buildings. However, it is not true. The system consists of various accessories that can be successfully used for the construction of individual objects.

BAUT® system has been used to accomplish projects in many countries and has enabled the implementation of architectural ideas.

- Brackets

- auxiliary elements

- fixing of brackets

- hooks for the brick lintels

- hooks for stretcher course brickwork

- hooks for soldier course brickwork

- hooks for rowlock course brickwork

- hooks for combined brickwork

- reinforcement

- wall ties

- metal anchors

- glass fibre plastic ties

- basalt fibre wall ties

- ventilation boxes

- baut system

- bautopas

- stainless steel brackets for brick veneer facades

NAMU TEKSTILE, LLC was launched in October, 2003. The main activity of the company is production of various textile products that are made of natural materials (natural sheep wool, linen or cotton). 60% of all NAMU TEKSTILE, LLC clients are hotels, hospitals, kindergartens and other companies.

We offer custom–made bedding, towels and other products made of 100% cotton.

On the request of choosey clients we also produce bedding from linen, corrugated cotton and sateen materials. Wide range of bedding is supplemented with bed sheets and bedcovers. On cooler evenings we may offer you to cover yourself with natural wool plaid or just wear warm vest or cloak. Since various types of saunas are getting more and more popular nowadays, we offer sauna accessories: aprons, caps, robes, sponges, seat mats, various towels etc. On customer's request we embroider, produce other accessories: decorative pillows, linen roses, wattled and weaved mats, tablecloths, napkins etc. NAMU TEKSTILE, LLC offers a wide range of textile products for you and your home

Our bedding is produced from various types of materials, may be in different sizes and colours. Most of our production is intended for hotels, rural tourism granges, hospitals, kindergartens, textile shops. Bedding patterns and colours are constantly updated to fit modern trends. On client's request we sew–in zippers, embroider initials or company logo, arrange different types of sets.

Recommendations

Modern market is constantly supplemented with various beddings that come in different sizes. Therefore before buying bedclothes we recommend to measure your bedroom belongings: blanket, pillows and mattress. When buying a simple bed sheet it is necessary to add up at least 20 cm overlap so that bed sheet would smoothly lay and wouldn’t be too small. When buying a fitted bed sheet everything is vice versa – such bed sheet should match mattress’s measurements. When buying blanket or pillow slips we recommend 2–5 cm larger slips because natural fabrics are predisposed to shrink during washing process (especially linen or linen–cotton blends).

Advice

Even when you buy the most expensive and qualitatively produced bedding, there is a doubt if it will look good and be durable if you take inadequate care of it. Here are some advices:

• The thinner the material, the softer should be its care;

• Sateen and cotton (light colours) garments may be washed at 60 °C temperature;

• To avoid fading, brighter colours (especially bluish, violet and claret shades) are recommended to wash at 40°C temperature;

• The brighter are the colours of a new garment, the more times you should wash it separately from other laundry;

• Blanket and pillow cases should be turned inside out and washed with colour–garment washing machine program at 40°C temperature;

• White laundry may be washed at 90 °C temperature;

• Bedding should be washed at least once a week;

• When washing the bedding it is essential to sort it by colours. Darker colours may colour lighter clothes and any other garments. It is essential to pay attention to care instructions and follow them.

Majority of people spend more time in bed than wearing casual clothing. Usually we do not forget to wash our clothes but our bedding is washed not as often as it should be. Health and good sleep is more important than the time spent for launder.

Sateen

During the production of regular cotton, very gentle and thick material is obtained; this material is called sateen. Sateen bedding is easy to wash, easy to iron, fast to dry, pleasant to the body and cools during those hot summer nights.

Perfect present for those who appreciate style and exclusivity.

Material: 100% cotton

Corrugated sateen

Exclusively beautiful and high quality bedding that does not require ironing. Such bedding is resistant to multiple washes, does not lose its softness and remains pleasant to the body just like as regular sateen. Corrugated sateen bedding is a great choice for those who are practical and appreciate quality.

Material: 100% cotton

Corrugated cotton

Bedding that does not require ironing. Special crumple effect gives additional exclusivity. Corrugated cotton bedding also has a great quality and price ratio.

Material: 100% cotton

Cotton

When talking about cotton covers, cotton bedding is gentle and pleasant to use, easy to wash, easy to iron, fast to dry and suitable for allergic adults and children. Such bedding is youthful, modern, available in non–traditional solid colours, geometrical or classic floral prints.

Material: 100% cotton

Linen

Various researches have proven that linen is the best material for bedding. Linen bedding is durable, non–allergenic, evenly distributes the natural sweat throughout the bedding so that human body temperature would remain even. Choose simple pattern, squared or even ornately embroidered bedding for sweet sleep and complete relaxation.

- Textile products

- production of various textile products

- natural materials

- natural sheep wool

- linen

- cotton

- bedding

- towels

- bedding from linen

- corrugated cotton

- sateen materials

- bed sheets and bedcovers

- sauna accessories

- aprons

- caps

- robes

- sponges

- seat mats

- various towels

- decorative pillows

- linen roses

- wattled and weaved mats

- tablecloths

- napkins

- Sauna products

- Plaids

- Children's products

- cotton trade

- personalised products

- produce

- sew and embroider bedding

- bedcovers

The pillows produced by the foam manufacturing plant Vita Blatic International, LLC have been tested by the respected laboratory Thomson Research Associates Europe).

We have been issued a certificate verifying that the polyurethane foam pillows fully meet the Ultra-Fresh antimicrobial requirements. This is another international recognition of high professionalism of the manufacturers of Lithuanian foam and the quality of our products.

We pay attention not only to the quality of our products, but to the proper storage of chemical raw materials, transportation and safe production technology. The specialists of the experienced manufacturer of chemical raw materials BorsodChem have carried out an inspection of safety of chemical raw materials at our plant and evaluated it as "A" Excellent.

Vita Blatic International, LLC was incorporated in 1997. Foam manufacturing plant was built in Southern Lithuania, on the outskirts of Alytus . The company belongs (is part of) the "VITA GROUP ", one of the largest polyurethane producers in the world. Overall investment including construction of the state-of-the-art manufacturing facility and purchase of foam production and processing lines, incorporating the latest technology, totalled to EUR 18.3 million. The company is committed to continuous expansion of its manufacturing and technology base. Highest quality raw materials are exclusively supplied by the most prominent companies of the chemical industry. The company is the leader of PU foam market in the Baltic states. The production is exported into 12 countries. The production conforms to the highest EU requirements for quality and environment protection.

Company management principles:

ensurance of requirements for occupational safety and health;

"Vita Group" company performance model;

quality management activities.

In 2010, visco-elastic polyurethane foam, employed by the foam production plant Vita Baltic International UAB, has won two highest evaluation awards of Lithuanian company products - gold medal for the Lithuanian Product of the Year and Innovation Prize in the category of the Innovative Product.

High resilience polyurethane foam (HR foam) product of UAB "Vita Baltic International" has been awarded the title of "Lithuanian Product of the Year 2001".

On December of 2006, European Association of Flexible Polyurethane Foam Blocks Manufacturers (EUROPUR) has certified all brands of polyurethane as measuring up to the highest standards and requirements of CertiPUR. High quality Lithuanian polyurethane and different articles are exported to 12 foreign manufacturers of upholstered furniture.

Flexible polyether and polyester foam in black and white laminated with fabric made of cotton and/or polyamide in different colours, have been recognised as conforming to the Oeko-Tex standard 100 and suitable for sewing and orthopaedic purposes.

Vita Blatic International, LLC has won the national contest of "Innovation Prize 2009" in the category of "Innovative Companies".

All types of the manufactured foams have quality and hygiene certificates. Combustion modified foams are certified by authoritative laboratories.

In 2010–2012 JSC “Pakaita“ participated in the project “Protective Responsive Outer Shell for People in Industrial Environments“ (PROSPIE). The partners of this project: Netherlands, Belgium, Denmark, Italy, Switzerland, United Kingdom, Germany, Lithuania.

In the Prospie-project a new generation of personal protective equipment (PPE) was developed and produced. The special feature of the PPE is a dynamic cooling system that prevents the worker to become hyperthermic. Although sweat evaporation is an excellent cooling mechanism for work in the heat, this system is compromised when working in protective clothing. The body temperature rises and consequently the vigilance and task performance decrease. Eventually the worker has to abandon his task due to incompensable heat strain.

Prospie aims to supply the worker with personal protective equipment that enables him or her to work longer in protective clothing with less discomfort. Innovative cooling methods, like forced ventilation, phase change materials and encapsulated endothermic salts, is integrated with protective clothing. Sensors in the suit measure relevant physiological data, such as skin temperature, heat flux and heart rate, to assess the thermal status of the worker, and the environmental conditions (temperature, relative humidity). The physiological signals are used in an algorithm that generates a warning signal when a certain safety threshold is surpassed. Data also is transferred to industrial safety systems in order to alert rescue workers if needed. The operational benefit of prototypes of the suit is determined in a controlled setting as well as in the industry where protective suits are indispensable.

The results is disseminated to standardization organizations, the industry and public procurement organizations. A training program will be made that focuses on the acceptability of the system by SME’s and end-users.

Although the system aims to contain the newest technology, human factors and practical usability including for instance ease of cleaning are leading in the design of the prototypes.

About JSC “Pakaita“

JSC “Pakaita“ was founded in 1945 in Kaunas. Company specializes in production:

● of tricot fabrics with capacity of 60 tons per month,

● tricot garments with capacity of 20000 psc. per month,

● drapery, curtains, bedspreads,

● sewing and knitting services.

Products/services:

Tricot fabrics for: sports, light outdoor clothes and underwear, fabrics for lining, pockets, flags

Technical tricot fabrics: materials for passenger seats, upholstery, mattresses, footwear, lining

Development of knitted/tricot fabrics. Company could help to develop new material according ideas and needs of the client. Knitted fabrics are produced from various type of yarns, such as: polyester (Trevira-dry fit), polyamide (Meryl®, Tactel ®, Supplex®), elastic (Lycra®,elaspan®), viscose, modal, viscose-Supersoft, Siro, comfortjet air jet cotton and their blends.

Tricot garments.

Styling execution: development of collection and collection presentation according ideas and needs of the client.

Technical creation: basic patterns for samples, samples making, grading and puzzling for production (GERBER technology programming equipment), technological documentation for samples and production.

Business partners: Company’s production is sold in domestic market and exported to Latvia, Estonia, Sweden, Denmark, Netherlands, Germany, Finland, Russia and Belarus

Strengths of the company: company offers short production time, small quantity orders, high quality.

Business interests: looking for wholesalers, retailers and customers on CMT base.

- Production of tricot fabrics

- production of tricot garments

- drapery

- curtains

- bedspreads

- sewing and knitting services

- Tricot fabrics for sports

- light outdoor clothes

- underwear

- fabrics for lining

- pockets

- flags

- technical tricot fabrics materials for passenger seats

- upholstery

- Mattresses

- footwear

- lining

- development of knitted tricot fabrics

- knitted fabrics

- polyester

- polyamide

- elastic

- viscose

- modal

- viscoseSupersoft

- Siro

- comfortjet air jet cotton and their blends

- tricot garments

- styling execution

- development of collection and collection presentation according ideas and needs of the client

- basic patterns for samples

- samples making

- grading and puzzling for production

- GERBER technology programming equipment

- technological documentation for samples and production

Dear Customer, it is our pleasure to introduce the Mazeikiai enterprise, UAB “MiGiris”. The enterprise’s main production is a popular household electric grater greatly loved by homemakers. The grater construction allows a large production output to be achieved, even as much as 80 kilograms of vegetables per hour, thereby saving precious time in preparing food in compeers to a food processor.

They operate quietly, are very easy to disassemble for cleaning, vibrate very little,and make an excellent gift for homemakers.

DOMESTIC ELECTRIC GRATER MACHINE

Domestic electric vegetable grater is a dream of every goodwife. A long time ago making of everybody’s beloved dishes such as “cepelinai”(Lithuanian meal, big dumpings made of potato dough and usually stiffed with minced meat), “vedarai” (kind of sausage, made of grated potatoes stuffed into entrails and baked in the oven), kugel, and other dishes from vegetables was a long and hard work but now after obtaining of Mazeikiai Joint Stock Company’s “MiGiris” grater machine “BETM” it is only a pleasure to prepare such dishes!

The grater is very productive, with the help of it you can grater even 80 kg vegetables per hour, it goes quietly, makes a little vibration, uses a little of electric power, it is very easy to clean as it can be easily unpicked, and the most important thing is that it is really not expensive.

All the family will be happy about this grater. It is the main production of Mazeikiai company “MiGiris”. In addition to this, company makes, rewraps and repairs various electric engines, metal constructions, founds color metal and plastic details in mechanical and repousse way.

Company “MiGiris” concerns about your welfare, because every goodwife will be happy getting such a wonderful present- Joint Stock Company’s “MiGiris” vegetable grater

We hope that this information will help you decide to make us your partner in the kitchen.

- Production of domestic appliances

- electric motors

- household appliances

- manufactures domestic electric grating machines

- manufacturing

- electric grating machine

- potato grating

- Metal processing

- thermal

- turnery

- routing

- grindering

- welding

- electric motors rewinding

- provides tooling

- punching

- aluminium and plastic moulding services

- Rewinding and repairs of electric motors

- production of metal constructions

● Made in Lithuania ● Maintenance ● Warranty ● Spare parts

LLC "PRINTMARK GROUP" is a technological enterprise, specializing in manufacturing and sales of industrial printing machines and materials.

- Industrial printing machines

- labelling equipments

- industrial printing materials

- manufacturers of printing mashines

- label printers

- standart label printers

- industrial label printers

- mobile printers

- textile printers

- card printers

- accessories

- software

- cleancer

- troubleshooting

- print and apply

- labels

- label fabric

- codding equipments

- high rate ballistic