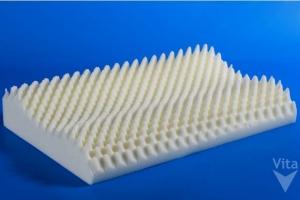

The pillows produced by the foam manufacturing plant Vita Blatic International, LLC have been tested by the respected laboratory Thomson Research Associates Europe).

We have been issued a certificate verifying that the polyurethane foam pillows fully meet the Ultra-Fresh antimicrobial requirements. This is another international recognition of high professionalism of the manufacturers of Lithuanian foam and the quality of our products.

We pay attention not only to the quality of our products, but to the proper storage of chemical raw materials, transportation and safe production technology. The specialists of the experienced manufacturer of chemical raw materials BorsodChem have carried out an inspection of safety of chemical raw materials at our plant and evaluated it as "A" Excellent.

Vita Blatic International, LLC was incorporated in 1997. Foam manufacturing plant was built in Southern Lithuania, on the outskirts of Alytus . The company belongs (is part of) the "VITA GROUP ", one of the largest polyurethane producers in the world. Overall investment including construction of the state-of-the-art manufacturing facility and purchase of foam production and processing lines, incorporating the latest technology, totalled to EUR 18.3 million. The company is committed to continuous expansion of its manufacturing and technology base. Highest quality raw materials are exclusively supplied by the most prominent companies of the chemical industry. The company is the leader of PU foam market in the Baltic states. The production is exported into 12 countries. The production conforms to the highest EU requirements for quality and environment protection.

Company management principles:

ensurance of requirements for occupational safety and health;

"Vita Group" company performance model;

quality management activities.

In 2010, visco-elastic polyurethane foam, employed by the foam production plant Vita Baltic International UAB, has won two highest evaluation awards of Lithuanian company products - gold medal for the Lithuanian Product of the Year and Innovation Prize in the category of the Innovative Product.

High resilience polyurethane foam (HR foam) product of UAB "Vita Baltic International" has been awarded the title of "Lithuanian Product of the Year 2001".

On December of 2006, European Association of Flexible Polyurethane Foam Blocks Manufacturers (EUROPUR) has certified all brands of polyurethane as measuring up to the highest standards and requirements of CertiPUR. High quality Lithuanian polyurethane and different articles are exported to 12 foreign manufacturers of upholstered furniture.

Flexible polyether and polyester foam in black and white laminated with fabric made of cotton and/or polyamide in different colours, have been recognised as conforming to the Oeko-Tex standard 100 and suitable for sewing and orthopaedic purposes.

Vita Blatic International, LLC has won the national contest of "Innovation Prize 2009" in the category of "Innovative Companies".

All types of the manufactured foams have quality and hygiene certificates. Combustion modified foams are certified by authoritative laboratories.

In 2010–2012 JSC “Pakaita“ participated in the project “Protective Responsive Outer Shell for People in Industrial Environments“ (PROSPIE). The partners of this project: Netherlands, Belgium, Denmark, Italy, Switzerland, United Kingdom, Germany, Lithuania.

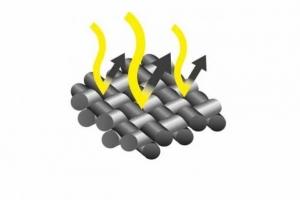

In the Prospie-project a new generation of personal protective equipment (PPE) was developed and produced. The special feature of the PPE is a dynamic cooling system that prevents the worker to become hyperthermic. Although sweat evaporation is an excellent cooling mechanism for work in the heat, this system is compromised when working in protective clothing. The body temperature rises and consequently the vigilance and task performance decrease. Eventually the worker has to abandon his task due to incompensable heat strain.

Prospie aims to supply the worker with personal protective equipment that enables him or her to work longer in protective clothing with less discomfort. Innovative cooling methods, like forced ventilation, phase change materials and encapsulated endothermic salts, is integrated with protective clothing. Sensors in the suit measure relevant physiological data, such as skin temperature, heat flux and heart rate, to assess the thermal status of the worker, and the environmental conditions (temperature, relative humidity). The physiological signals are used in an algorithm that generates a warning signal when a certain safety threshold is surpassed. Data also is transferred to industrial safety systems in order to alert rescue workers if needed. The operational benefit of prototypes of the suit is determined in a controlled setting as well as in the industry where protective suits are indispensable.

The results is disseminated to standardization organizations, the industry and public procurement organizations. A training program will be made that focuses on the acceptability of the system by SME’s and end-users.

Although the system aims to contain the newest technology, human factors and practical usability including for instance ease of cleaning are leading in the design of the prototypes.

About JSC “Pakaita“

JSC “Pakaita“ was founded in 1945 in Kaunas. Company specializes in production:

● of tricot fabrics with capacity of 60 tons per month,

● tricot garments with capacity of 20000 psc. per month,

● drapery, curtains, bedspreads,

● sewing and knitting services.

Products/services:

Tricot fabrics for: sports, light outdoor clothes and underwear, fabrics for lining, pockets, flags

Technical tricot fabrics: materials for passenger seats, upholstery, mattresses, footwear, lining

Development of knitted/tricot fabrics. Company could help to develop new material according ideas and needs of the client. Knitted fabrics are produced from various type of yarns, such as: polyester (Trevira-dry fit), polyamide (Meryl®, Tactel ®, Supplex®), elastic (Lycra®,elaspan®), viscose, modal, viscose-Supersoft, Siro, comfortjet air jet cotton and their blends.

Tricot garments.

Styling execution: development of collection and collection presentation according ideas and needs of the client.

Technical creation: basic patterns for samples, samples making, grading and puzzling for production (GERBER technology programming equipment), technological documentation for samples and production.

Business partners: Company’s production is sold in domestic market and exported to Latvia, Estonia, Sweden, Denmark, Netherlands, Germany, Finland, Russia and Belarus

Strengths of the company: company offers short production time, small quantity orders, high quality.

Business interests: looking for wholesalers, retailers and customers on CMT base.

The pillows produced by the foam manufacturing plant Vita Blatic International, LLC have been tested by the respected laboratory Thomson Research Associates (Europe). We have been issued a certificate verifying that the polyurethane foam pillows fully meet the Ultra-Fresh antimicrobial requirements. This is another international recognition of high professionalism of the manufacturers of Lithuanian foam and the quality of our products.

We pay attention not only to the quality of our products, but to the proper storage of chemical raw materials, transportation and safe production technology. The specialists of the experienced manufacturer of chemical raw materials BorsodChem have carried out an inspection of safety of chemical raw materials at our plant and evaluated it as "A" Excellent.

Vita Blatic International, LLC was incorporated in 1997. Foam manufacturing plant was built in Southern Lithuania, on the outskirts of Alytus . The company belongs (is part of) the "VITA GROUP ", one of the largest polyurethane producers in the world. Overall investment including construction of the state-of-the-art manufacturing facility and purchase of foam production and processing lines, incorporating the latest technology, totalled to EUR 18.3 million. The company is committed to continuous expansion of its manufacturing and technology base. Highest quality raw materials are exclusively supplied by the most prominent companies of the chemical industry. The company is the leader of PU foam market in the Baltic states. The production is exported into 12 countries. The production conforms to the highest EU requirements for quality and environment protection.

Company management principles:

ensurance of requirements for occupational safety and health;

"Vita Group" company performance model;

quality management activities.